PRODUCTION ADVANTAGE

We specialize in packaging machine for 20 years, we meet the needs of customers of various specifications and best-selling in world market by stable quality and factory price.

SERVICE ADVANTAGE

We have a 10-year marketing team, one to one after-sales service for all customers.

DELIVERY ADVANTAGE

our machines are very popular at home and abroad, we have some standard equipment in stock, customize machine normally delivery in advance, we have our own professional transport chain.

Related Products

More items about capping machine

We Have The Best Solutions for Your Business

Wenzhou Tuoyi Machinery Co., Ltd. is a technological machinery enterprise integrating R&D, manufacturing and sales. ave a group of experienced machinery R&D and sales teams.

Our main products are capping machine, cartoning machine, cellophane wrapping machine, film packaging machine, film wrapping machine, food cartoning machine, horizontal cartoning machine, labeling machine, liquid filling machine, overwrapping machine, pharmaceutical cartoning machine, sealing machine, shrink packaging machine, shrink wrap machine, shrink wrapping machine, sticker labeling machine, wine labeling machine,. If you are interested in that, please contact us for more information.

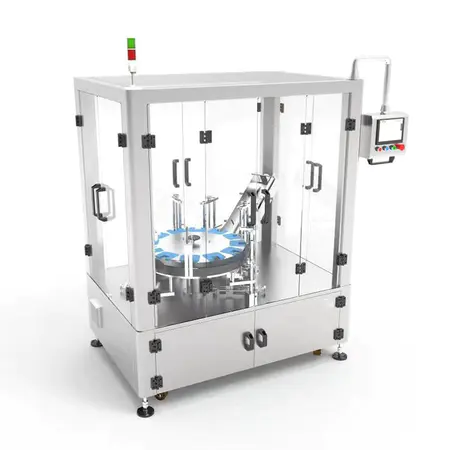

Characteristics of Capping Machines

Capping machines exhibit various characteristics that contribute to their functionality and versatility. They are designed to accommodate different types and sizes of caps, making them adaptable to diverse packaging requirements. Capping machines can handle various closure mechanisms, such as screw caps, snap-on caps, or press-on caps. They may incorporate adjustable components to accommodate different bottle or container sizes. Additionally, capping machines can be constructed using durable materials that withstand the demands of continuous operation in industrial settings.

Functions of Capping Machines

The primary function of a capping machine is to apply caps or closures onto bottles or containers securely. These machines can perform a range of tasks, including cap sorting, cap orientation, cap tightening, and torque adjustment. Some advanced capping machines may integrate additional features like cap sterilization, cap presence detection, or cap quality inspection. Overall, the main function of a capping machine is to automate and optimize the cap sealing process, ensuring consistent and reliable results.

Application Fields for Capping Machines

Capping machines find applications in various industries, including food and beverage, pharmaceuticals, cosmetics, chemical manufacturing, and many more. They are essential in packaging processes that require reliable sealing, such as bottling beverages, sealing pharmaceutical containers, or capping cosmetic products. Capping machines are utilized wherever product integrity, safety, and quality control are critical. They cater to a wide range of container sizes and cap types, making them versatile across different industries.

What is the development trend of capping machine?

The outstanding feature of the development of capping machines is diversity, that is, the diversity of concepts, standards, methods and development trends. The research, improvement and development of capping machines have extended beyond the scope of packaging itself and products to many business fields. The capping machine is no longer an independent device. It is not only changed by the change of the product, but also bears the function of protecting the product and serving us, which can not only express the value of the product, but also increase the added value of the product.

Frequently Asked Question

Do you have any question?

The main types are:①No sealing material sealing machine. Including hot-pressing, cold-pressing, fusion-welding, plug-in, folding and other sealing machines.②There is a sealing material sealing machine. Including rotary type, knurling type, crimping type, pressing type and other sealing machines.③There is an auxiliary sealing material sealing machine. Including tape type, adhesive type, staple type, ligation type, suture type and other sealing machines

There are many kinds of capping machines, including pneumatic, electric, semi-automatic, fully automatic.The principle is generally based on the rubbing type, that is, the cover is tightened by friction.

There is a vacuum gauge on the vacuum capping machine, and the degree of vacuum gauge can be seen during the vacuuming process; after vacuuming, you can also use a separate vacuum gauge to test the vacuum degree.