PRODUCTION ADVANTAGE

We specialize in packaging machine for 20 years, we meet the needs of customers of various specifications and best-selling in world market by stable quality and factory price.

SERVICE ADVANTAGE

We have a 10-year marketing team, one to one after-sales service for all customers.

DELIVERY ADVANTAGE

our machines are very popular at home and abroad, we have some standard equipment in stock, customize machine normally delivery in advance, we have our own professional transport chain.

Related Products

More items about horizontal cartoning machine

We Have The Best Solutions for Your Business

Wenzhou Tuoyi Machinery Co., Ltd. is a technological machinery enterprise integrating R&D, manufacturing and sales. ave a group of experienced machinery R&D and sales teams.

Our main products are capping machine, cartoning machine, cellophane wrapping machine, film packaging machine, film wrapping machine, food cartoning machine, horizontal cartoning machine, labeling machine, liquid filling machine, overwrapping machine, pharmaceutical cartoning machine, sealing machine, shrink packaging machine, shrink wrap machine, shrink wrapping machine, sticker labeling machine, wine labeling machine,. If you are interested in that, please contact us for more information.

Automation for Increased Efficiency and Reduced Labor Costs

By automating the cartoning process, a horizontal cartoning machine significantly improves efficiency and reduces labor costs. The machine operates at high speeds, allowing for rapid packaging of products. It eliminates the need for manual carton formation, loading, and closure, freeing up labor resources to focus on other tasks. The automation provided by the horizontal cartoning machine results in streamlined operations, increased productivity, and cost savings for businesses.

Ensure the safety of man and machine

The automatic shutdown function of mechanical overload is adopted to ensure the safety of man and machine.The fault display alarm system is adopted, which is convenient for maintenance and handling of faults.

Main performance characteristics

1. It adopts packaging forms such as automatic feeding, box opening, boxing, batch numbering, box sealing, waste rejection, etc., with simple operation, stable operation and low noise.

2. Using PLC and man-machine interface automatic control system, stepless frequency conversion speed regulation, high efficiency and low energy consumption.

3. Adopt international famous brand electrical components, stable and reliable performance.

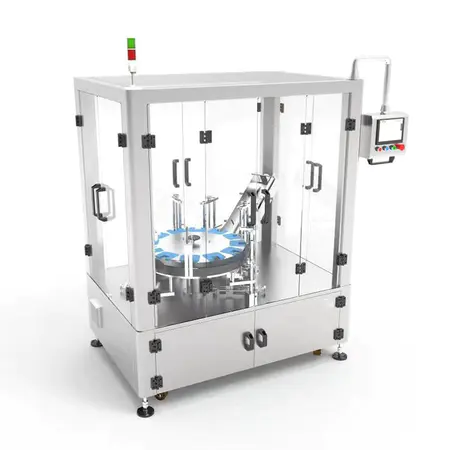

Efficient Packaging with a Horizontal Cartoning Machine

A horizontal cartoning machine is a valuable asset in the packaging industry, enabling efficient and automated carton formation, loading, and closure. With this machine, products are packaged in a horizontal orientation, providing stability and precise control during the packaging process. The horizontal cartoning machine streamlines operations, improves productivity, and ensures consistent packaging quality.

Frequently Asked Question

Do you have any question?

The horizontal cartoning machine can not only be used alone, but can also be used in conjunction with blister packaging machines, three-dimensional transparent film packaging machines, labeling machines, inkjet printers and other equipment to form a complete packaging production line.

The whole process of packaging and forming of the horizontal cartoning machine is also divided into four stages: lowering the box, opening, filling, and closing the cover.

The way of cartoning is different from that of vertical cartoning. Generally, vertical cartoning is that objects are discharged from top to bottom or topped from bottom to top, while horizontal cartoning machines generally use cartons lying down. The carton is pushed from the side, this method requires the product to be relatively regular and easy to push. Like facial masks, multi-purpose boxes for food and daily necessities, the products are output horizontally by the conveyor belt. The vertical cartoning machine products are vertically output by the conveyor belt.